Custom Earbuds - OEM / ODM

What can Wellyp do for you?

Seeking more selections to enrich the wearable categories in your shop?

Looking for a trendy earset to promote your brands/slogans with?

Creating a personalized earphone style to convey your own identification?

More functions with less expensive earphones from China?

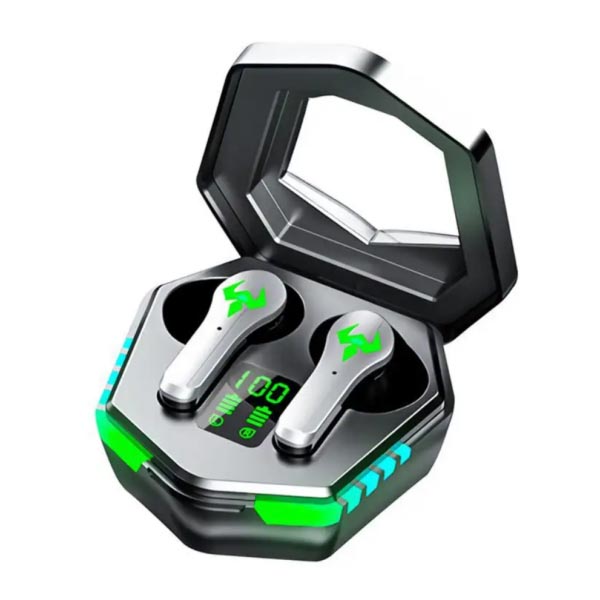

China Custom TWS & Gaming Earbuds Supplier

Enhance the impact of your brand with wholesale personalized earbuds from the best custom headset wholesale factory. To get the most optimal returns for your marketing campaign investments, you need functional branded products that offer ongoing promotional appeal while being useful to clients in their everyday lives. Wellyp is a top-rated OEM earbuds supplier which can provide a variety of options when it comes to finding the perfect custom headsets to fit the needs of both your customer and your business.

How To Create a Earbuds Brand

Creating a headphone brand involves conducting market research, developing a business plan, determining the brand name and image, producing a prototype, manufacturing, testing and certification, marketing and sales, and finally launching the brand. Therefore, choosing an experienced and skilled earbuds manufacturer can ensure the continuous output of high-quality earbuds.

Besides,The materials used in the production of headphones are important for ensuring good sound quality and comfort. Common materials include plastic, metal, silicone, foam, and others, and the specific choices will depend on the brand positioning and product characteristics. For certain special features and performance requirements, such as waterproofing and noise reduction, specialized materials and technologies may be needed to achieve them. If you are planning to start your own earphone brand and don’t know how to start a earbuds brand, here is what you need to know.

Define The Appearance Of Your Own Earbuds Brand

Defining the appearance of your own earbuds brand involves considering various factors, including the brand's target audience, the brand's personality, and the brand's value proposition. Here are some steps to help you define the appearance of your earbuds brand:

1.Brand Image: First, determine what your brand image is, such as fashion, sports, high-end, etc. This will help you determine the overall style of the headphone design.

Before starting to create a brand, it's essential to understand the market and target audience you're working in. You need to identify market size, competitors, price ranges, consumer demands and preferences, and more. By researching the market and competition, you can identify differentiation points to establish your foothold in the market.

It's crucial to know your target audience as well. You need to identify their age, gender, income, interests, behavior, and other traits to determine how to market your product and ensure that your brand and product can attract their attention.

3.Design Concept: You need to consider your brand's design concept. For example, you may want the headphone appearance to have elements such as simplicity, innovation, and technology.

4.Material Selection: Choosing the right material is crucial to defining the headphone appearance. You need to choose high-quality materials to ensure the appearance of the headphones is exquisite and durable. For example, you can choose metal, ceramic, or composite materials.

5.Color Selection: You need to choose the appropriate colors that match your brand image and design concept, such as black, white, gold, silver, blue, etc. You can choose a single color, two colors, or multiple colors, but you must ensure that the color matching is coordDecide on the shape and size: The shape and size of your earbuds are critical to their appearance and functionality. Consider the ergonomics and how well they fit in the ear when selecting the design.

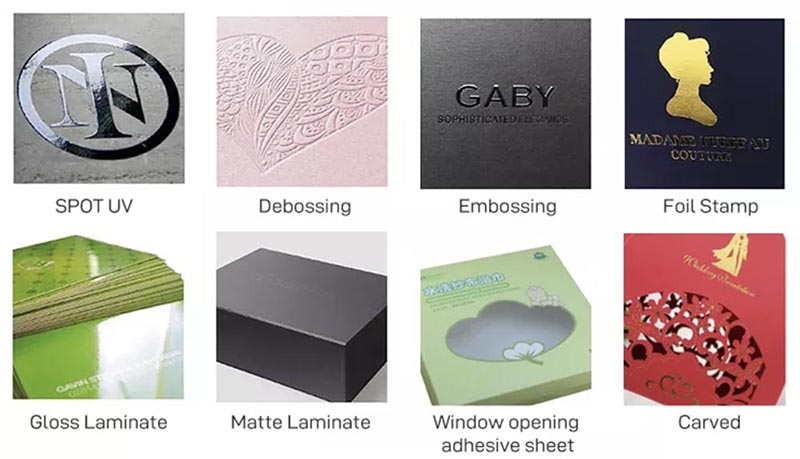

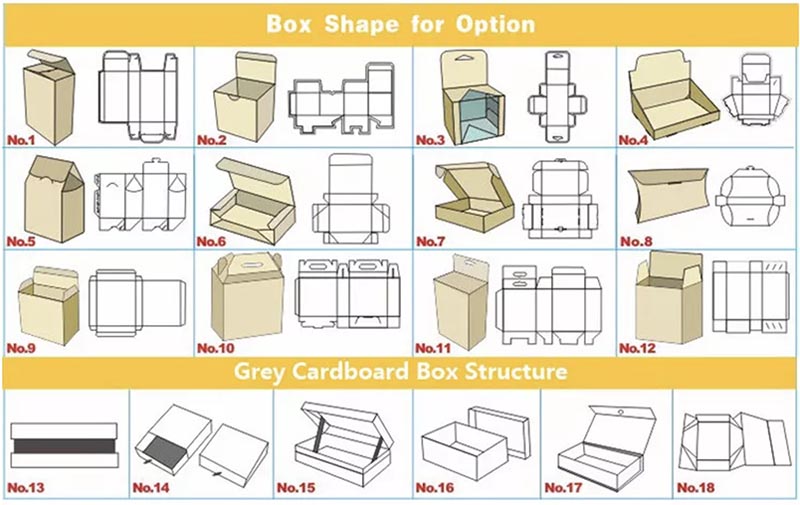

6.Consider packaging and branding: The packaging of your earbuds can also play a significant role in their appearance. Consider how you want to brand your product and what kind of packaging will be most attractive to your target audience.

7.Get feedback: Finally, get feedback from your target audience and make adjustments to your earbud design based on their preferences.

8.Detail Handling: Detail handling is essential for headphone appearance design. You need to carefully consider every detail, such as the material and color of the headphone cable, the design and material of the headphone plug, etc. You need to ensure that every detail can reflect your brand's image and concept.

9.Practicality: Finally, you also need to consider the practicality of the headphones, such as comfort, suitability for various ear shapes, portability, etc. This will help you design headphones that are both beautiful and practical.

By considering these factors, you can create an earbuds brand that not only looks great but also appeals to your target audience and reflects your brand's personality and value proposition.

Our OEM/ODM Advantages

Wellyp is a professional manufacturer and exporter of TWS earbuds, gaming earsets and ANC headphones since 2004. Located in Huizhou city, neighbouring to Hongkong and Shenzhen, a manufacturing region with unparalleled supportive supplychain in electronic industry, we carry out tasks more effectively than those in other parts of China.

First, Wellyp salesteam responses efficiently to your enquiry from the very beginning. With 15+ business years our staff are much experienced in understanding and satisfying customers’ demands, we share the know-how knowledge in how to develop a real earphone that a client loves ideally. In particular, we have been successfully creating various customised brands and ideas with exclusive earphone models over the past 10 years, which has enabled us to understand our potential customers in a profound way.

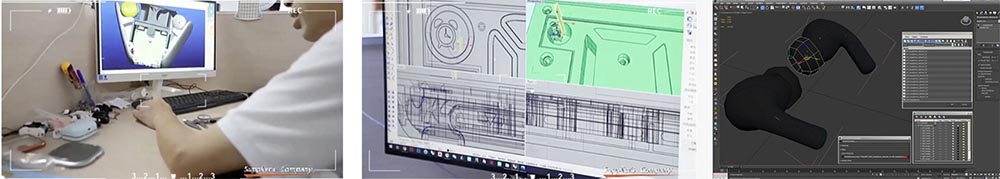

Secondly, our moulding workshop and assembling factory ensure us better control of moulding accuracy and workmanship. Our engineers edit the virtual parts of earphone templates with 3D Max. Following the layout approval, one of our EDM spark machines for tools, CNC machines, injection moulding machines are ready to create prototypes with real functions as preproduction samples to follow in mass production.

Coming to the next , we send prototype samples to our contracted printing factory to undertake customised color spray and brand/slogan printing. Different printing applies to the different printing processes, or is subject to customers’ demands----namely itching( laser engraving), pad printing, silk-screen printing, offset printing, or UV printing optional.

Last but not least, regulated quality inspection and battery/electronics aging-test must be desperately made before packing and shipment. Each piece of the order you receive must have met criteria of certifications executed in your markets.

RF Testing

Curve Test

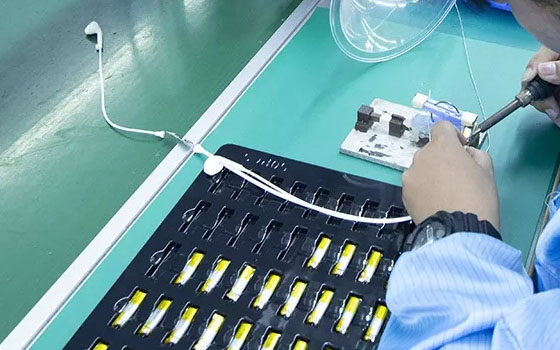

Welding the Battery

Testing the Circuit Board

Aging Test

Warehouse

How does Wellyp realize your idea/programme into earphones?

This screen-shot email might be an example of your inquiry. To receive our response more efficiently you are suggested to include as detailed as possible the enquired product name, expected functions, 2D/3D drawings/sketches with technical data, and sample pictures if available. We are immediately reachable through emails, phones, Whatsapps, Wechats, or Skypes.

3D engineers are working on product models

In certain cases, we might create a 3D full-scale mockup of your headphone built with 3D printer. This unique technology benefits us in saving lengthy sampling time and expensive sample set-up charges, enabling your strong competence against other rivals.

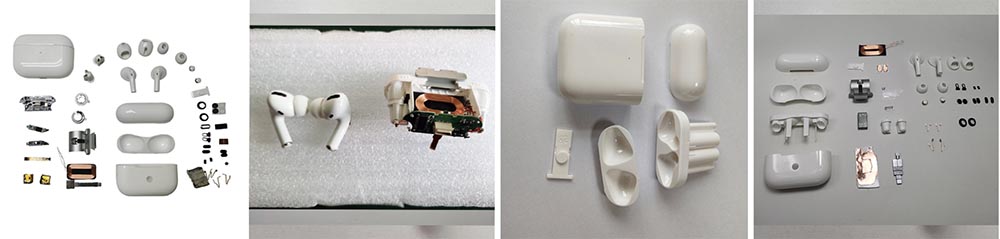

Once a 3D-printed mockup sample has primarily been approved by customers, we pass all technical data/drawings/templates to our tooling workshop. Operated by skilled technicians, our advanced CNC tooling machines and EDM machines are the key players to create and itch alloy-metallic mould sets. This process may endure 25 to 50days before the mould set comes into being, subject to technical compatibility or structural complexity. Repeated modification on the mould finishing may often required due to the processing disruption over the period.

Outside materials composed of earphones are:

ABS plastics or Polycarbonate(PC)---the plastic part of headphone covers;

Sponge and PVC, PU leather, or silicone--- ear cushion/ear cap;

PVC or PU wrapping--- earphone cables.

Facilitated with 12 sets of injection moulding machines of different sizes and lifting weights, our productivity is capable enough to complete any order quantity, and our facilities are designed for 24-hour’s operation. Products in customized color or with brand relief are also injected in this stage.

In many cases customers might require various color combinations for their earphones, this leads to the next step---color spraying in our contracted paint-spraying factory. Necessarily, logos/ brands/slogans are also printed in the same factory after the spraying process ends.

We offer different solutions for logos/brandings/slogans: itching(i.e. laser engraving), pad printing, silk-screen printing, offset printing, or UV printing.

With more than 10 years of assembling experience, our well-equipped assembling lines and skilled workers are ready to carry out any task sheets continuously and effectively. Following the assembling steps listed on each work station, each step is observed and supervised scientifically to ensure every piece of earphones are correctly and properly assembled.

100% of the assembled pieces must undertake regulated quality inspection and battery/ electronics aging-test in the inspection room next to the assembling lines.

Our delivery time for quantity upto a 40 feet container would be around 30-40days after sample approval. In most cases quantity upto 10,000pcs would be within 20-25days after sample confimation. Importantly over the past 15 years we have established stable and trustable partnership with contracted worldwide logistic companies, who are supportive to offer us competitive enough air/sea freight rate. We are ready to offer CIF by air/sea term to your destination should you like to.

Creating Your Own Smart Earbuds Brand

Our in-house design team will help you with creating your completely unique earbuds & earphone brand